HSC-H High elasticity heat Shrinkable crimp splices

HSC-H High elasticity heat Shrinkable crimp splices

Applications

HCS-H is a heat shrinkable sleeve made by the combination of polyolefin and hot melt adhesive. It has strong adhesion to PVC, PE and metal. It is used to protect the connection, waterproof and anti-corrosion. It can strengthen the fixing and anti-vibration in a rough environment. It has a good function of insulating and protecting the electronic connector. Durable, easy to install, and low installation cost compared to conventional connectors.

Characteristics Shrinkage ratio 3:1 hot-melt adhesive provides excellent waterproof property Excellent stretch and mechanical damage resistance Ideally translucent provides tensile strength High elasticity keeps steady performance | Operating temperature range Operating temperature : -40℃~105℃ Minimum shrink temperature : 60?C fully recovery temperature : 100?C |

Technical Indicators

Test Item | Characteristics | Test condition | |

Unaged | Tensile strength | Min. 18MPa | Room temp. |

Aged

| Elongation | Min. 200% | |

Tensile strength | Min. 11.5MPa | 150℃/7 days | |

Elongation | Min. 100% | ||

Voltage withstand and breakdown Voltage(Unaged) | Withstand 2.5 KV for 1minute and breakdown | Room temp. | |

Voltage withstand and breakdown Voltage(Aged) | Withstand 2.5 KV for 1minute and breakdown at least half of unaged breakdown voltage | 150℃/7 days | |

Copper corrosion | No corrosion of bare copper | 150℃/7 days | |

Copper stability | No sign of degradation Min.Elongation 100% | 150℃/7 days | |

Cold bend | No crack | -40℃/4 hrs | |

Heat shock | No crack | 200℃/4 hrs | |

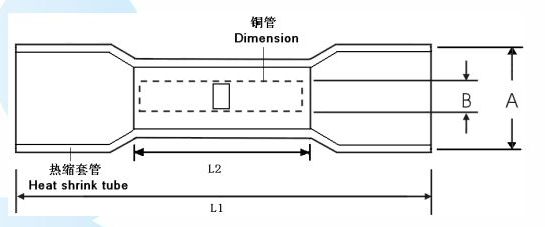

Product Dimensions

Part. No |

Wire Range | Copper Pipe | Heat shrink tube |

Insulator |

Color |

Approval | |||||

A.W.G | mm2 | OD | ID | L2 | OD | ID | L1 | ||||

HSC-H-1 | 22-18 | 0.5-1.0 | 3.8 | 1.7 | 15 | 6.1 | 5.0 | 36.0 | PE | Red | RoHS |

HSC-H-2 | 16-14 | 1.5-2.5 | 4.8 | 2.4 | 15 | 7.2 | 6.0 | 36.0 | PE | Blue | RoHS |

HSC-H-3 | 12-10 | 4.0-6.0 | 5.7 | 3.6 | 15 | 8.3 | 7.0 | 42.0 | PE | Yellow | RoHS |